In this tutorial I will take you step by step through the whole process of knife making and show you lots of pictures along the way as I make an actual knife. I will also give you tips and recommendations on what tools you can use, what steel to use and different ways you can do this.

I do have this whole tutorial in a pair of youtube videos where I show you the whole process of making this knife as I make it: Part 1 begins right here: Youtube video How to make a knife

Here is a look at the exact knife that I make in this tutorial:

Can you make a knife by this method? You sure can! Lots of people have done it and they sent me pics! You can check out those knives right here: Knives made by web visitors.

Step One Choosing The Steel

There are a lot of different types of steels and the distinctions revolve around a few basic additions variations. The most important part of the definition of steel is how much carbon has been added to iron to make it a certain grade of steel. The addition of carbon makes it much harder and the more carbon you add the harder the steel will be. But there is a point where the steel is so hard that it is brittle. And we don't want a brittle knife.

So here are a few quick guidelines for choosing steel:

If you are purchasing steel you can go with something in the medium to high carbon steel range. Common steels for knife making include 01 steel, W2 steel, L6 steel, or D2 Steel. I have more information about these steels here and there are also links to good knife steel that you can buy through amazon.com . If you are purchasing steel you can go with something in the medium to high carbon steel range. Common steels for knife making include 01 steel, W2 steel, L6 steel, or D2 Steel. I have more information about these steels here and there are also links to good knife steel that you can buy through amazon.com .

The picture to the left shows two pieces of 01 Steel that I purchased through amazon.com. They are two inches wide, eighteen inches long and one bar is 1/8 inch thick and the other is 3/16 inch thick.

This is some terrific steel for making a knife.

Step Two Designing your Knife

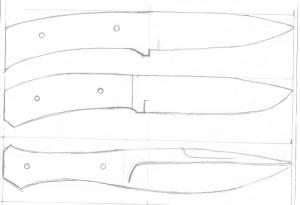

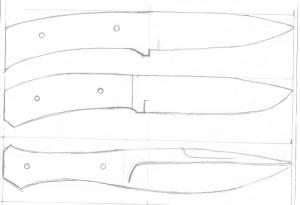

Before you start making your knife you have to know what you are going to make! This means drawing it out on paper and figuring out the size, handle, shape, bolsters, pins, ricasso, size of the tang and more. This all has to be decided upon before hand. Then you draw yourself a pattern on a piece of paper in the exact size of the whole knife

This picture shows three knife patterns that I drew out on paper. For this tutorial I am going to use the pattern in the center. (If you want this exact sheet with the three patterns you can download it here) If you have trouble printing this picture to size your printer may be fitting it to the page which makes it smaller. I have oriented this picture vertically so it will print easier. Try this one to see if it works better: download it here

Cut out the pattern and glue it to the piece of steel. I used a spray adhesive. And notice how I have placed the knife in a way that takes advantage of the edges. This way there will be less cutting to do. A good portion of the top of the knife and the butt of the knife are against the edge.

Step Three: Removing the Stock

Now it's time to do something called profiling the blade. This is where we remove all the metal that is not the knife! Use any tools that you can use. The best process that works for me is I used a hacksaw to cut away as much of the steel as I could. But a hacksaw only cuts in straight lines so we can't do any of the curved parts.

But by making multiple cuts we can still get rid of a lot of the steel.

Once I did all the hacksawing I could do I moved on to using a bench grinder. This works terrific and you can do a lot of the curved work here. Get it down to almost exactly the shape of the blade - but not quite. And don't try to force any curves that you can't quite get with the grinder. We will finish that off with a file.

I also used a one inch belt sander to continue working the shape of the blade.

Now we do the final profiling of the blade using a Mill File. Clamp it in a vise and get the profile exactly to it's final shape. And smooth out all the rough edges around the whole knife.

And there we go. The profile of the knife is completed.

Okay, let's move on to the next part of the knife making tutorial where we drill the holes for the handle and file in the bevel Okay, let's move on to the next part of the knife making tutorial where we drill the holes for the handle and file in the bevel

The Wonder of Knifemaking The Wonder of Knifemaking

Master smith Wayne Goddard is an icon in the field of knife making. As a full-time maker, teacher and writer, Goddard works as hard to teach knife making skills as he does to acquire them. His affiliation with BLADE Magazine has brought new and interesting information, tips and tricks to thousands of would-be knife makers. Other popular titles from Goddard include The Wonder of Knifemaking (2000) and $50 Knife Shop (2001 and 2006).

Basic Knife Making: From Raw Steel to a Finished Stub Tang Knife Basic Knife Making: From Raw Steel to a Finished Stub Tang Knife

Learn the craft of knifemaking. 205 color images and step-by-step instructions provide for all stages of construction, from selection of the steel, to forging the blade, assembling the handle, and constructing a holder.

Knife Engineering: Steel, Heat Treating, and Geometry

How to make the highest performing knives. A book for knife enthusiasts, knifemakers, and bladesmiths. Not a how-to on knifemaking or bladesmithing but an in-depth exploration of the effects of different steels, metallurgy, heat treatments, and edge geometries on knife performance. This book provides ratings for toughness, edge retention, and corrosion resistance for all of the popular knife steels. Micrographs of over 50 steels. Specific recommended heat treatments for each steel. And answers to questions like: 1) Does a thinner or thicker edge last longer? 2) What heat treatment leads to the best performance? 3) Are there performance benefits to forging blades? 4) Should I use stainless or carbon steel? All of these questions and more are answered by a metallurgist who grew up around the knife industry. Note: The book now has conversions to Celsius throughout after feedback from Global readers.

|

![]()

If you are purchasing steel you can go with something in the medium to high carbon steel range. Common steels for knife making include 01 steel, W2 steel, L6 steel, or D2 Steel.

If you are purchasing steel you can go with something in the medium to high carbon steel range. Common steels for knife making include 01 steel, W2 steel, L6 steel, or D2 Steel.