Let's start off with a long quote of exactly how the book starts out:

From the heavy axle and tire, down to the smallest rivet in the wagon, they were all made by the smith. From the heavy axle and tire, down to the smallest rivet in the wagon, they were all made by the smith.

Bells and bits as well as the ornamental parts of the harness, they were all made by the smith.

From the crowbar and spade down to the butcher and pocket knife, they were all made by the smith.

The carpenter's tools, from the broadax and adz down to the divider and carving steel, they were all made by the smith.

From the heavy irons in the fireplace down to the frying-pan and locks on the kitchen doors;

knives and forks on the dining-table, they were all made by the smith.

From the gun on the shoulder of the soldier and the saber in the hands of the officer, the spurs and pistol for the commander, they were all made by the smith.

From the heavy anchor and its chain to the smallest pulley in the rigging of the ship, they were all made by the smith.

From the weather vane on the church spire, and the clock in the tower down to the lock of the doors?

And the artistic iron cross over the graves in the church yard, they were all made by the smith.

No wonder, then, that the smith was respected.

That quote above is a strong reminder of things gone by and how valuable a blacksmith was. Today we have a limited view of the smith. We think swords. And maybe we even think horseshoes. But we surely don't think about how important a cog in the big wheel the smith was. I remember reading something about how a hundred years ago small towns used to advertise for blacksmths, making offer of a home, land and salary for any smith who would come work for them. That quote above is a strong reminder of things gone by and how valuable a blacksmith was. Today we have a limited view of the smith. We think swords. And maybe we even think horseshoes. But we surely don't think about how important a cog in the big wheel the smith was. I remember reading something about how a hundred years ago small towns used to advertise for blacksmths, making offer of a home, land and salary for any smith who would come work for them.

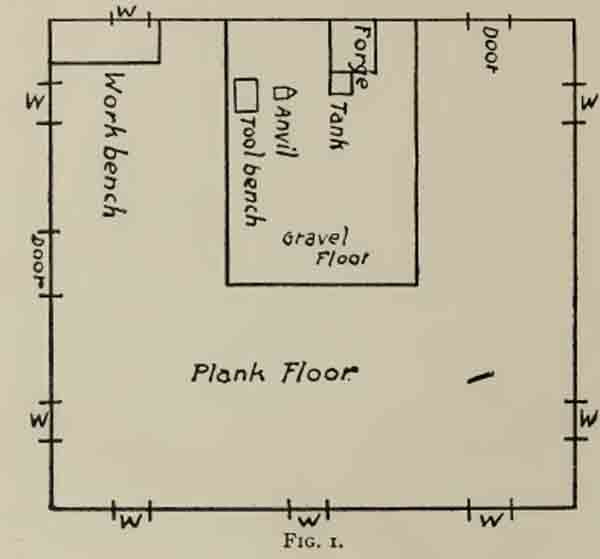

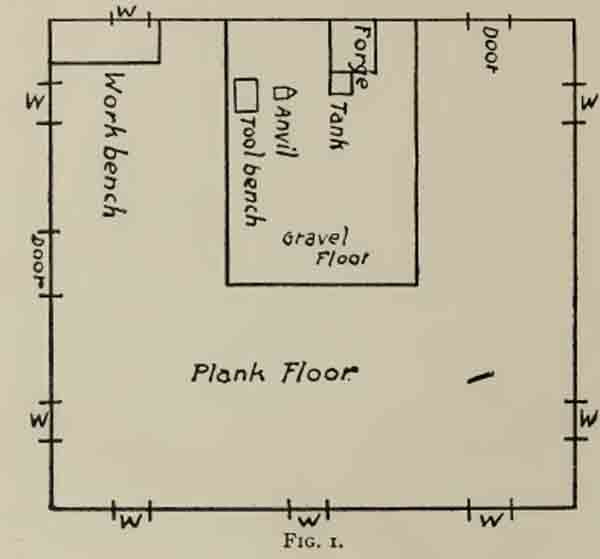

Here is their recommended diagram for a blacksmith shop. And below the illustration I have included what they say about the making and the design of it.

In building a shop care should be taken in making it convenient and healthy. Most of the shops are built with a high floor. This is very inconvenient when machinery of any kind is taken in for repairs, as well as in taking in a team for shoeing. Around the forge there should be a gravel floor. A plank floor is a great nuisance around the anvil. Every piece cut off hot is to be hunted up and picked up or it will set fire to it. I know there will be some objection to this kind of floor but if you once learn how to keep it you will change your mind.

To make this floor take sand and clay with fine gravel, mix with coal dust and place a layer where wanted about four inches thick. This floor, when a little old, will be as hard as iron, provided you sprinkle it every night with water. The dust and soot from the shop will, in time, settle in with it and it will be smooth and hard. It will not catch fire ; no cracks for small tools or bolts to fall through it will not crack like cement or brick floors. If your shop is large then make a platform at each end, and a gravel floor in the center, or at one side.

This floor is cool in summer and warm in winter, as there can be no draft. The shop should have plenty of Height, skylights if possible. The soot and dust will, in a short time, make the lightest shop dark. The shop should be whitewashed once a year. Have plenty of ventilation. Make it one story only if convenient to do so, as an upper story in a blacksmith shop is of very little use. The shop is the place where the smith spends most of his time and he should take just as much care in building it, as a sensible housekeeper does in the construction of her kitchen.

My thoughts - The first thing that comes to mind is the authors sense of how things will change over the years and how we build it now with that in mind. This was normal back then. But now we don't think past much further than the next tweet. And I found the placement of the tank and the door very interesting. The tank makes me think they did a whole lot of quenching back then. Probably due to the lesser quality of irons and steels. And the door, well. It seems to be placed in a way that the smith was facing it all day and could instantly see if someone arrived.

There is a whole lot of wonderful stuff including a lot about horses. From this book it appears that blacksmiths were also responsible for basic care of horses including treatment of problems. And there is a section about how to Put-in spokes on a wagon wheel.

And Whoa, I Was shocked to read this passage on how to harden files. Thank goodness we still don't do this.

HARDEN FILES

The best way to harden files is to have a cast iron bucket filled with lead. Heat it until the lead is red hot, then plunge the file into this, handle up. This will give a uniform heat and the file will not warp so easy if the heat is right. In cooling the file off, use a box four or five feet long with salt water in, run the file back and forth endwise, not sideways, that will warp the file, take it out of the water while yet sizzling. Now, if warped, set it between a device so that you can bend it right. While in this position sprinkle water over where you straighten until cold and the file will be right.

All in all just a wondeful book. I have learned a lot from it. If I could sum it all up in a few words? This is what I would say: All in all just a wondeful book. I have learned a lot from it. If I could sum it all up in a few words? This is what I would say:

How to make, how to mend, how to harden and how to sharpen.

Do you like making projects and exploring a variety of hobbies?

Sign up for my free newsletter. I give you regular updates on hobbies and projects you can make. it is totally free and I don't share your email with anybody.

|

![]()