Ok, so what exactly is a blacksmith forge?

A Blacksmith needs a forge for one simple reason. Burning fire or coal doesn't get hot enough to heat steel to the point where it can be worked. Yup! That is pretty much it. Wood will begin to burn at around 500 degrees fahrenheit and under normal conditions can get up to around 900 or 1000 degrees fahrenheit. But steel doesn't get very workable until at least 1400 degrees, and if you want to forge two pieces of steel together you have to get the temperature up around 2000 degrees.

So how do we get the temperature up that high?

Two things help us achieve this higher temperature. First we use the right burning material and secondly we force air onto it. So, a forge holds the burning materials in a safe and accessible way and contains it in a way so air can be forced over through it.

Heating steel is quite an amazing thing. It transforms in color as it gets hotter. And this is one of the fundamental things a blacksmith looks for. Will has a neat color chart of heating steel right here.

Coal is a great material for burning because it burns at a much higher temperature than regular wood, and depending on the amount of air that is available it can burn very hot - in excess of 3500 degrees fahrenheit. The available air is important because it is a chemical reaction that is happening. And if you blow air through the coal you make more air available for the chemical reaction.

So a forge uses coal and some kind of method for blowing air onto and through the coal. That's pretty much the whole of it. From there we have lots of varations in forge shapes and sizes.

A forge pretty much has three characteristics. First it safely holds burning coal in a way that can be accessed by the smith. Second it provides a stream of air that flows through the pile of coal. And third it provides a way to handle the burnt up and used up coal ash.

Let's take a look at a few forges.

Here is a really simple forge that I made out of the deck from a lawn mower. It uses a hair dryer as the blowing force. Pretty simple setup but it works quite well. I have a tutorial on how to make something like this right here.

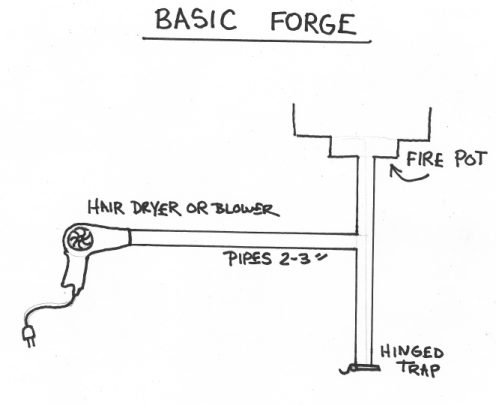

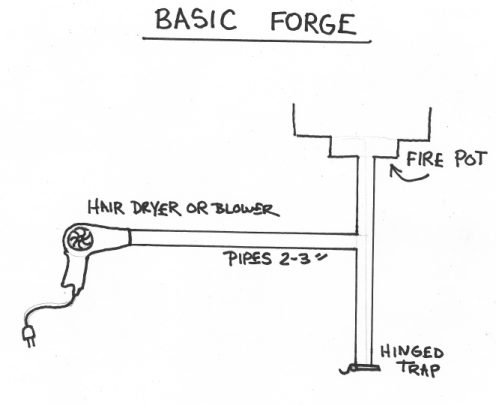

Here is the basic setup for most forges.

You can see our three characteristics. The blower provides air. The Fire pot holds the coal and the hinged trap provides a way to remove the ash and burnt up materials.

Some Variations of Forges

Let's first take a look at these three forges. The first is a simple dish shaped forged. This is very traditional and the way many blacksmiths have worked for a hundred years. The second picture shows a gas fired forge. Which is an inexpensive and convenient thing for forging. It is a small gas forge designed for knife making. The third picture shows a very specialized forge that I built for sword making. It has a line of air going along the length so a whole sword can be heat at one time.

Bellows! I would be remiss if I didn't mention bellows. Because when we think of a blacksmith in medieval times we picture him working at a bellows blowing on the forge. It is true, that's what it does and you now know that it the bellows forces air on the fire and makes it hotter! This is a picture of a forge setup made by Oliver. He is a web visitor and my thanks go to him for sharing the pic with us.

Some other forge variations:

Here is a forge made by Atilla. He is a web visitor and was kind enough to share a pic of his forge with us. It is a brick forge. The outer bricks are the standard red brick but the inner bricks are special heat resistant bricks like the ones used in wood stoves. In the picture you can see a silver pipe going into the forge. That is the air supply.

Here is a brake drum forge made by Brett. A brake drum from a truck is a very popular choice for making a home made forge. Many people do it because it is simple, easy and readily available. The brake drum is itself very durable and capable of easily handling the heat of the coal.

About Coal: (Other things can be used)

This is something that a lot of people ask about. I talked all about coal in this tutorial and coal is one of the best choices for blacksmithing but there are other options that are quite good. For example you can use something called Hardwood Lump Charcoal for a forge. It works quite well and I use it all the time. It is hardwood that has been burnt under pressure which concentrates the carbons. This causes it to burn much hotter than regular wood. You can buy it just about anywhere they sell grills and grill supplies including Home Depot. Amazon has it:

Cowboy 24220 Lump Charcoal, 20-Pound

This ends my lesson on what a blacksmith forge. I do have lots of other resources you might be interested in including pictures of dozens of forges that people have sent me right here: Peoples forges.

I also have a page where you can check out the prices of forges right here

Do you like making projects and exploring a variety of hobbies?

Sign up for my free newsletter. I give you regular updates on hobbies and projects you can make. it is totally free and I don't share your email with anybody.

|

![]()