Blacksmithing is believed to have been started in 1,500 B.C. in what is now Syria. " Blacksmithing began with the Iron Age, when primitive man first began making tools from iron."( Blacksmithing History 1".1978). Blacksmithing probably began with very crude tools of stone to work the metal after it was heated, probably in a campfire. It was discovered that meteorites had iron in them as well as the red layer of rock strata (Blacksmithing History 1".1978). The raw iron ore was brought to places called bloomeries and smelted down for use by the blacksmith to use. The earliest ironworks were located in areas where iron, flux, and fuel were ample and in proximity to each other. This was due to the weight of the ore and fuel needed to work the iron (Blacksmithing History 1".1978). In the bloomeries were small furnaces built from rocks that could withstand repeated heating. These furnaces looked like beehives with a vent in the top and an entry portal on the side (Blacksmithing History 1".1978). The raw iron was brought here and placed in the furnaces and heated until it melted. Once the furnace cooled the still red hot iron blooms as they were called were pulled from the furnace and pounded into rectangular bar that were folded over and over to produce wrought iron. Wrought Iron had a very low carbon content making it much weaker than steel. But wrought iron was very malleable, a property that lends itself to forging and forge welding ( Blacksmithing History 1".1978). A long time after that, blacksmithing remained a crude art. It took three thousand years for man to learn the science of metallurgy. Long after man made the first simple tools--the first spear or arrow tips--the craft would require hundreds more years before blacksmiths understood the magnetic properties of iron welding (Blacksmithing History 1".1978). To fuel the smelter or the forge, wood is converted to charcoal, or coal is converted to coke. Destructive distillation, the process name, means burning the raw fuel with limited oxygen (Blacksmithing History 1".1978). Blacksmithing is believed to have been started in 1,500 B.C. in what is now Syria. " Blacksmithing began with the Iron Age, when primitive man first began making tools from iron."( Blacksmithing History 1".1978). Blacksmithing probably began with very crude tools of stone to work the metal after it was heated, probably in a campfire. It was discovered that meteorites had iron in them as well as the red layer of rock strata (Blacksmithing History 1".1978). The raw iron ore was brought to places called bloomeries and smelted down for use by the blacksmith to use. The earliest ironworks were located in areas where iron, flux, and fuel were ample and in proximity to each other. This was due to the weight of the ore and fuel needed to work the iron (Blacksmithing History 1".1978). In the bloomeries were small furnaces built from rocks that could withstand repeated heating. These furnaces looked like beehives with a vent in the top and an entry portal on the side (Blacksmithing History 1".1978). The raw iron was brought here and placed in the furnaces and heated until it melted. Once the furnace cooled the still red hot iron blooms as they were called were pulled from the furnace and pounded into rectangular bar that were folded over and over to produce wrought iron. Wrought Iron had a very low carbon content making it much weaker than steel. But wrought iron was very malleable, a property that lends itself to forging and forge welding ( Blacksmithing History 1".1978). A long time after that, blacksmithing remained a crude art. It took three thousand years for man to learn the science of metallurgy. Long after man made the first simple tools--the first spear or arrow tips--the craft would require hundreds more years before blacksmiths understood the magnetic properties of iron welding (Blacksmithing History 1".1978). To fuel the smelter or the forge, wood is converted to charcoal, or coal is converted to coke. Destructive distillation, the process name, means burning the raw fuel with limited oxygen (Blacksmithing History 1".1978).

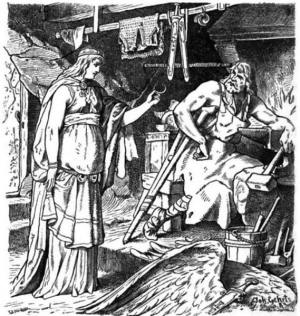

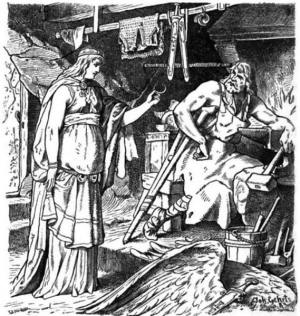

As things progressed into the Iron Age as this period became know as the smith was held in high regard. The most skilled smiths could rise to high positions in the social hierarchy and become very powerful in their own right (American council of learned societies, 1987). But in some cases the smiths were branded evil. Some villages banned Blacksmithing as a black art in the middle ages with anyone caught practicing the craft being put to death. What went on in the darkness of the smithy was a mystery to most people. Many stories evolved about the man of fire, and some people say that this is where the stories of the Devil in burning hell started ( Grant-Jones, S., 2011). . It is interesting to note that at that time, blacksmiths were respected artisans. Their ability to 'conjure' objects and weaponry from crude iron ore was regarded in much the same light as the revered alchemist ( Pollock, J. 2010). So highly regarded was the smith in ancient Wales that he had a place of honor in the princes court alongside the priest and the poet. There was a blacksmith among the gods on Olympus. His name was Hephaestus, son of Zeus and Hera, later known as Vulcan among the Romans (Bealer, Alex W. 1969). As things progressed into the Iron Age as this period became know as the smith was held in high regard. The most skilled smiths could rise to high positions in the social hierarchy and become very powerful in their own right (American council of learned societies, 1987). But in some cases the smiths were branded evil. Some villages banned Blacksmithing as a black art in the middle ages with anyone caught practicing the craft being put to death. What went on in the darkness of the smithy was a mystery to most people. Many stories evolved about the man of fire, and some people say that this is where the stories of the Devil in burning hell started ( Grant-Jones, S., 2011). . It is interesting to note that at that time, blacksmiths were respected artisans. Their ability to 'conjure' objects and weaponry from crude iron ore was regarded in much the same light as the revered alchemist ( Pollock, J. 2010). So highly regarded was the smith in ancient Wales that he had a place of honor in the princes court alongside the priest and the poet. There was a blacksmith among the gods on Olympus. His name was Hephaestus, son of Zeus and Hera, later known as Vulcan among the Romans (Bealer, Alex W. 1969).

The blacksmith was called the king of trades because of his ability to create his own tools. Compared to other trades of the time all of their tools came from the blacksmith. Trades such as smithing were considered more important than blacksmithing but to me blacksmithing played a more important role in history. With out the blacksmith parts for the advancement of technology would never have been created.

As this whole iron industry evolved over time, blacksmithing became an umbrella for several specialties ( Blacksmithing History 1".1978). The mostly remembered version of the blacksmith is that of a handyman. Call him the "village smithy". The differentiation lies mainly in that his shop was not geared for making one particular type of product ( Blacksmithing History 1".1978). His shop was the local hardware store. He could also repair a log chain or put rims on the wagon wheels or fix the axe that got chipped when it hit a rock. Whether the village needed swords or plowshares, the blacksmith made them. For without the blacksmith, the village could not survive ( Blacksmithing History 1".1978). The role of the Blacksmith was very diverse not only was he the local toolmaker and "engineer" he was sometimes called upon to act as Dentist, Doctor, Undertaker ,Veterinary surgeon and horse dealer ( Blacksmithing History 1".1978). Many other professions sprouted up under the umbrella of blacksmithing. Smiths who focused mainly on blades were called blade smiths. Those who worked on armour were called amours.

For centuries blacksmiths experimented with metals to try and create stronger metals. The hardening and tempering processes were invented. They also learned different ways to modify the carbon content of the iron, thus allowing iron to be used for even more purposes ( Blacksmithing History 1".1978). Blacksmiths found that smelting iron with carbon produced a stronger metal which was later called "crucible steel". By 1,500 BC, the European Hittites had conquered present-day Syria and began smelting iron. They were the first known civilization to make wrought iron. Centuries later, Damascus would lend its name to pattern-welded iron ( Blacksmithing History 1".1978). It also took many years for blacksmiths to discover the magnetic properties of iron. After the discovery that iron was magnetic compass were created and a new era in exploration was made possible.

Blacksmithing was believed to have started in what is now Syria and moved west into Europe. In the time of exploration many explores such as Leif Erikson and Christopher Columbus brought blacksmiths with them on their voyages. Leif Ericson, Christopher Columbus and all the other European discoverers brought blacksmiths on their travels to the New World. Had they not done so, the trip could have been one way and possibly ended somewhere in the mid-Atlantic ( Blacksmithing History 1".1978). Now the question is posed who was the first to blacksmith in the Americas. In 1001, Lief Ericsson built a settlement, L'Anse aux Meadows, on Cape Bauld, Newfoundland and excavations have uncovered an ironworks and forge.[1] The Norsemen found iron nodules in the bogs and streambeds near their settlement. Though primitive and small in scope, the Norse ironworks were most likely the first in the New World ( Blacksmithing History 1".1978). Blacksmithing was believed to have started in what is now Syria and moved west into Europe. In the time of exploration many explores such as Leif Erikson and Christopher Columbus brought blacksmiths with them on their voyages. Leif Ericson, Christopher Columbus and all the other European discoverers brought blacksmiths on their travels to the New World. Had they not done so, the trip could have been one way and possibly ended somewhere in the mid-Atlantic ( Blacksmithing History 1".1978). Now the question is posed who was the first to blacksmith in the Americas. In 1001, Lief Ericsson built a settlement, L'Anse aux Meadows, on Cape Bauld, Newfoundland and excavations have uncovered an ironworks and forge.[1] The Norsemen found iron nodules in the bogs and streambeds near their settlement. Though primitive and small in scope, the Norse ironworks were most likely the first in the New World ( Blacksmithing History 1".1978).

As settlements were begin built in the new world a key part of the building of these villages were blacksmiths. Villages were dependant on the blacksmith to provide tools such as axes and plows for them to maintain there ways of life. Because of the weight of iron ore, a constant amount could not be shipped from Europe. Wherever iron ore was found, a small industry began. And with these small steps, blacksmiths could start making tools, farm implements, muskets, cooking utensils, knives, and nearly all of the necessities (even sewing needles and fish hooks) that a sustainable pioneer village would need ( Blacksmithing History 1".1978). By 1700, some areas were prospering and had many of the amenities that you would expect to find in any well-developed town or city. The Boston area is such an example ( Blacksmithing History 1".1978).

During the Iron Age horses were a very important part of the blacksmiths business. As stated before blacksmiths were sometimes horse dealers and were also relied upon to shoe the horses. Chances are that the horses that made it here did not get shod because horseshoes were bulky and expensive to ship from Europe. Without developed roads, there wasn't a great demand for wagons--wagon parts, springs, and hardware were built by blacksmith shops back then ( Blacksmithing History 1".1978). The age of the horse was a great source of employment for the old time Blacksmiths and the decline of horses being used for transport and labor has brought about the demise of the traditional country smithy ( Grant-Jones, S. 2011).

As the Iron Age began to enter the 18 th century a revolution in melting and make steel was created. An important date in this century is 1793--Eli Whitney received a patent for the cotton gin machine. Whitney was somewhat of a genius when it came to mass-producing identical metal parts ( Blacksmithing History 1".1978). The advances in Iron production that were made in the late 1700's started what is now termed as the industrial revolution, and was responsible for the conversion of a manual labor based production system to one of complete mechanization, cast and wrought iron was now being used to make these machines that would eventually cause the demise of hand-crafted work and would eventually signal the end of the road for the traditional worker in

Iron ( Grant-Jones, S. 2011). Henry Bessemer took out a patent to produce steel from pig iron in 1855; this could produce steel far more effectively and cheaper than it was to produce wrought iron ( Grant-Jones, S. 2011). Thus, the date of 1793 might well represent the dawn of the age of the Industrial Revolution, an age where metal tools and parts would be mass-produced. Cotton became an export product as a result. More cotton was planted--more plows were forged--more wagons were needed to haul the cotton to market--better roads had to be built--and blacksmiths provided these tools. But mass- production techniques being pioneered in the late 1700's would eventually replace much of the blacksmith's work ( Blacksmithing History 1".1978).

As time passed and the 19 th century began blacksmiths began to play a smaller role in society. "A key date in this period is 1838. John Deere invented a superior plow made from steel. His design turned the soil better than existing plows. But what made this event significant was the use of steel" (Blacksmithing History 1" 1978). After Henry Bessemer revolutionized the production of steel and made it cheaper to produce than wrought iron more smiths and factories began to use it. Steels durability quickly made it the most used metal in the industrial revolution. As the industrial age progressed the role of the blacksmith was minimized. "The blacksmith shop was starting to change as well. The bellows was replaced with a rotary fan blower and the drill press became available for small blacksmith shops. In larger shops and some of the fledgling factories, one might find a steam-powered trip hammer" (Blacksmithing History 1" 1978). " With the development of factories and their ability to create basic products cheaply and in large numbers, the position of the blacksmith within this industrializing society became less important and went into decline. Within the present 21st century, blacksmiths in the Western world are pretty much a dying breed" ( Pollock, J. 2010). But without the blacksmith the parts to create the machine in the factories never would have been created. This role that the blacksmith played in setting up the machinery that went into factories paved the way to the modern world.

As the industrial era moved along more and more factories began sprouting up all across America many of which replaced the village smith. A good example of this comes in the form of the nail. "Nails were expensive. Lumber, on the other hand, was becoming cheap. And as lumber got cheaper, people wanted to live in houses instead of log cabins. A way to make cheap nails had to be found and it was--the nail factory" (Blacksmithing History 1" 1978). In the times before mass produced nails, nails represented wealth. And with the advent of factory nails this representation of wealth vanished over night. "Nails were so scarce and expensive prior to 1800 that some states had previously enacted arson laws, not to criminalize arson per se, but to prevent people from burning down sheds, barns, and houses just to sift the nails from the ashes! Factories such as Wheeling's LaBelle Nail Co. (1852, and still operating in 2010) met the demand for nails. And they forever removed one of the blacksmith's product lines" (Blacksmithing History 1" 1978). "Horses, wagons, and horse-drawn implements would dominate the blacksmith's work through this period. Factories would begin producing many of the tools traditionally made in the village smithy. And steel, not iron became the metal of choice. By 1910, Henry Ford had made a farm tractor that most farmers could afford. Along with his Model T automobile, Henry Ford would make the horse and wagon almost obsolete." (Blacksmithing History 1" 1978).

As the 20 th century came into full swing the blacksmith was almost completely obsolete. Even with all of the factories there were some blacksmiths still working on specialty items and other such items. "There was a golden age for blacksmiths who made architectural ironwork during the early part of this period. But the Great Depression (1930) would end this Renaissance. Still, many of America's most-treasured iron works in iron were made during this time." (Blacksmithing History 1 1978). A lot of banks and industry buildings commissioned blacksmiths to create ornamental ironwork for the out and inside of their buildings. But as the Great Depression rolled around this work all but stopped. And with this the art of blacksmithing all but went extinct. "In summary, the art of blacksmithing almost became extinct during the latter half of this period. People would remember their grandfather's farm and the shed where his anvil was set up" (Blacksmithing History 1 1978).

As the 20 th century moved along in about 1970 the art of blacksmithing experienced a resurgence. " Enough grandchildren must have been curious about Grandpa's anvil because a resurgence in blacksmithing began about 1970." (Blacksmithing History 1 1978). Even with resurgence the amount of blacksmiths is still a very small number. " The quality of work, especially in the arts, is more impressive now than it's ever been. There is more of a market for metal sculpture now than at any other time. The quality of work of today's blade smiths and gunsmiths rivals any time in history. But rather than arm a village, today's workmanship is primarily sold to collectors.

While the styles and nature of architectural ironwork changes from decade to decade, we are seeing some truly fantastic work today. But you will never see banks commission window and door grilles as they once did. Nor will your university install iron gates at its entrance." (Blacksmithing History 1, 1978). The blacksmith was once a staple in the success of technological advances, but now is a distant memory of what they once were.

The blacksmith was once a symbol of hard work and the mastery of the elements. Now they are a memory only brought up in history classes and seen working only in presentations of the older times. The only place you will see blacksmiths practicing are at places like the renaissance festivals and Amish villages. It is sad how the craft that was once so relied upon is now such a distant fleeting dream in the memories of few.

References

- American council of learned societies.(1987)."Metallurgy". Dictionary of the middle ages.(8). Canada: Cottier Macmillan Canada Inc.

- "Blacksmithing History 1".(1978). Appalachian Blacksmiths Association. August, 21,2012, from WWW.Appaltree.net

- Grant-Jones , S.(2011)." History of the Blacksmith". Simon Grant-Jones, August 21,2012 from WWW.simongrant-jones.com

- Pollock, J. (2010). "The history of blacksmithing- Wroughters of Iron". The History Of. August 22, 2012 from thehistoryof.net

- Bealer, Alex W.(1969). The art of Blacksmithing. Castle Books

Bibliography

- American council of learned societies.(1987)."Metallurgy". Dictionary of the middle ages.(8). Canada: Cottier Macmillan Canada Inc.

- "Blacksmithing History 1".(1978). Appalachian Blacksmiths Association. August, 21,2012, from WWW.Appaltree.net

- Grant-Jones , S.(2011)." History of the Blacksmith". Simon Grant-Jones, August 21,2012 from WWW.simongrant-jones.com

- Pollock, J. (2010). "The history of blacksmithing- Wroughters of Iron". The History Of. August 22, 2012 from thehistoryof.net

- Bealer, Alex W.(1969). The Art of Blacksmithing

Castle Books Castle Books

The Art of Blacksmithing The Art of Blacksmithing

With more than 500 illustrations, this book is perfect for craftsmen who want to set up a blacksmith shop, and for lovers of history and craft alike. This book describes and illustrates the equipment and techniques developed in more than six thousand years of working iron by hand.

Indeed, this unique book covers every aspect of a fascinating and little-known art, the fundamental craft on which the civilization of the Iron Age was built.

The Blacksmith (Colonial People)

Do you like making projects and exploring a variety of hobbies?

Sign up for my free newsletter. I give you regular updates on hobbies and projects you can make. it is totally free and I don't share your email with anybody.

|

![]()

As things progressed into the Iron Age as this period became know as the smith was held in high regard. The most skilled smiths could rise to high positions in the social hierarchy and become very powerful in their own right (American council of learned societies, 1987). But in some cases the smiths were branded evil. Some villages banned Blacksmithing as a black art in the middle ages with anyone caught practicing the craft being put to death. What went on in the darkness of the smithy was a mystery to most people. Many stories evolved about the man of fire, and some people say that this is where the stories of the Devil in burning hell started ( Grant-Jones, S., 2011). . It is interesting to note that at that time, blacksmiths were respected artisans. Their ability to 'conjure' objects and weaponry from crude iron ore was regarded in much the same light as the revered alchemist ( Pollock, J. 2010). So highly regarded was the smith in ancient Wales that he had a place of honor in the princes court alongside the priest and the poet. There was a blacksmith among the gods on Olympus. His name was Hephaestus, son of Zeus and Hera, later known as Vulcan among the Romans (Bealer, Alex W. 1969).

As things progressed into the Iron Age as this period became know as the smith was held in high regard. The most skilled smiths could rise to high positions in the social hierarchy and become very powerful in their own right (American council of learned societies, 1987). But in some cases the smiths were branded evil. Some villages banned Blacksmithing as a black art in the middle ages with anyone caught practicing the craft being put to death. What went on in the darkness of the smithy was a mystery to most people. Many stories evolved about the man of fire, and some people say that this is where the stories of the Devil in burning hell started ( Grant-Jones, S., 2011). . It is interesting to note that at that time, blacksmiths were respected artisans. Their ability to 'conjure' objects and weaponry from crude iron ore was regarded in much the same light as the revered alchemist ( Pollock, J. 2010). So highly regarded was the smith in ancient Wales that he had a place of honor in the princes court alongside the priest and the poet. There was a blacksmith among the gods on Olympus. His name was Hephaestus, son of Zeus and Hera, later known as Vulcan among the Romans (Bealer, Alex W. 1969).  Blacksmithing was believed to have started in what is now Syria and moved west into Europe. In the time of exploration many explores such as Leif Erikson and Christopher Columbus brought blacksmiths with them on their voyages. Leif Ericson, Christopher Columbus and all the other European discoverers brought blacksmiths on their travels to the New World. Had they not done so, the trip could have been one way and possibly ended somewhere in the mid-Atlantic ( Blacksmithing History 1".1978). Now the question is posed who was the first to blacksmith in the Americas. In 1001, Lief Ericsson built a settlement, L'Anse aux Meadows, on Cape Bauld, Newfoundland and excavations have uncovered an ironworks and forge.[1] The Norsemen found iron nodules in the bogs and streambeds near their settlement. Though primitive and small in scope, the Norse ironworks were most likely the first in the New World ( Blacksmithing History 1".1978).

Blacksmithing was believed to have started in what is now Syria and moved west into Europe. In the time of exploration many explores such as Leif Erikson and Christopher Columbus brought blacksmiths with them on their voyages. Leif Ericson, Christopher Columbus and all the other European discoverers brought blacksmiths on their travels to the New World. Had they not done so, the trip could have been one way and possibly ended somewhere in the mid-Atlantic ( Blacksmithing History 1".1978). Now the question is posed who was the first to blacksmith in the Americas. In 1001, Lief Ericsson built a settlement, L'Anse aux Meadows, on Cape Bauld, Newfoundland and excavations have uncovered an ironworks and forge.[1] The Norsemen found iron nodules in the bogs and streambeds near their settlement. Though primitive and small in scope, the Norse ironworks were most likely the first in the New World ( Blacksmithing History 1".1978).